Tool Room Capabilities

Electrical Discharging Machine [EDM]:-

High-precision EDM Machining uses a cutting tool to remove metal material, Electrical Discharge Machining (EDM) directs high-frequency electrical sparks from an electrode to vaporize electrically conductive metals. The type of EDM is known as sinker EDM, or die sink EDM. There is also Wire EDM and hole drilling EDM.

EDM is widely used in mold and die making because it works so well on hard materials like titanium, enables more complex shapes and designs than mechanical cutting machines can produce and doesn’t put any mechanical force into the work piece. The surface quality of finished molds also tends to be of higher quality with EDM than with mechanical cutting technologies.

LATHE:-

A lathe machine is a machine tool that is used to remove metals from a workpiece to give a desired shape and size. The machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis.

MILLING:-

Milling is a process performed with a machine in which the cutters rotate to remove the material from the work piece present in the direction of the angle with the tool axis. With the help of the milling machines one can perform many operations and functions starting from small objects to large ones.

The milling machines are also known as the multi-tasking machines (MTMs) which are multi-purpose machines capable of milling and turning the materials as well. The milling machine has got the cutter installed up on it which helps in removing the material from the surface of the work piece. When the material gets cooled down then it is removed from the milling machine.

RADIAL DRILLING:-

A drilling machine with the drill spindle in a tool head and saddle that are movable along a projecting arm which itself can be rotated about a vertical column.

Radial drilling machines are used to drill mediums to large and heavy workpieces. These machines are used to drill holes in a given radial distance. It is mainly used when the component’s size is larges in height.

Radial drilling machines are primarily designed for drilling holes in heavy jobs or workpieces. Since heavy work cannot move much, the radial drilling machine is made in such a way that the machine tool can move any part of heavy work without doing much work.

SURFACE GRINDING:-

Surface Grinding Machine is a machine in which a grinding wheel is used as a cutting tool for removing the material from the surface of the workpiece. It is also called an abrasive machining process where abrasives are placed on the surface and corners of the grinding wheel so as to do the finishing process with much more accuracy.

Each Abrasive particle acts as a single point cutting tool whereas the grinding wheel, with full of abrasives called a multi-point cutting tool

Grinding Process is one of the widely accepted finishing operations because of its material removal capacity in a very small size of chips ranging from 0.25 to 0.5 mm.

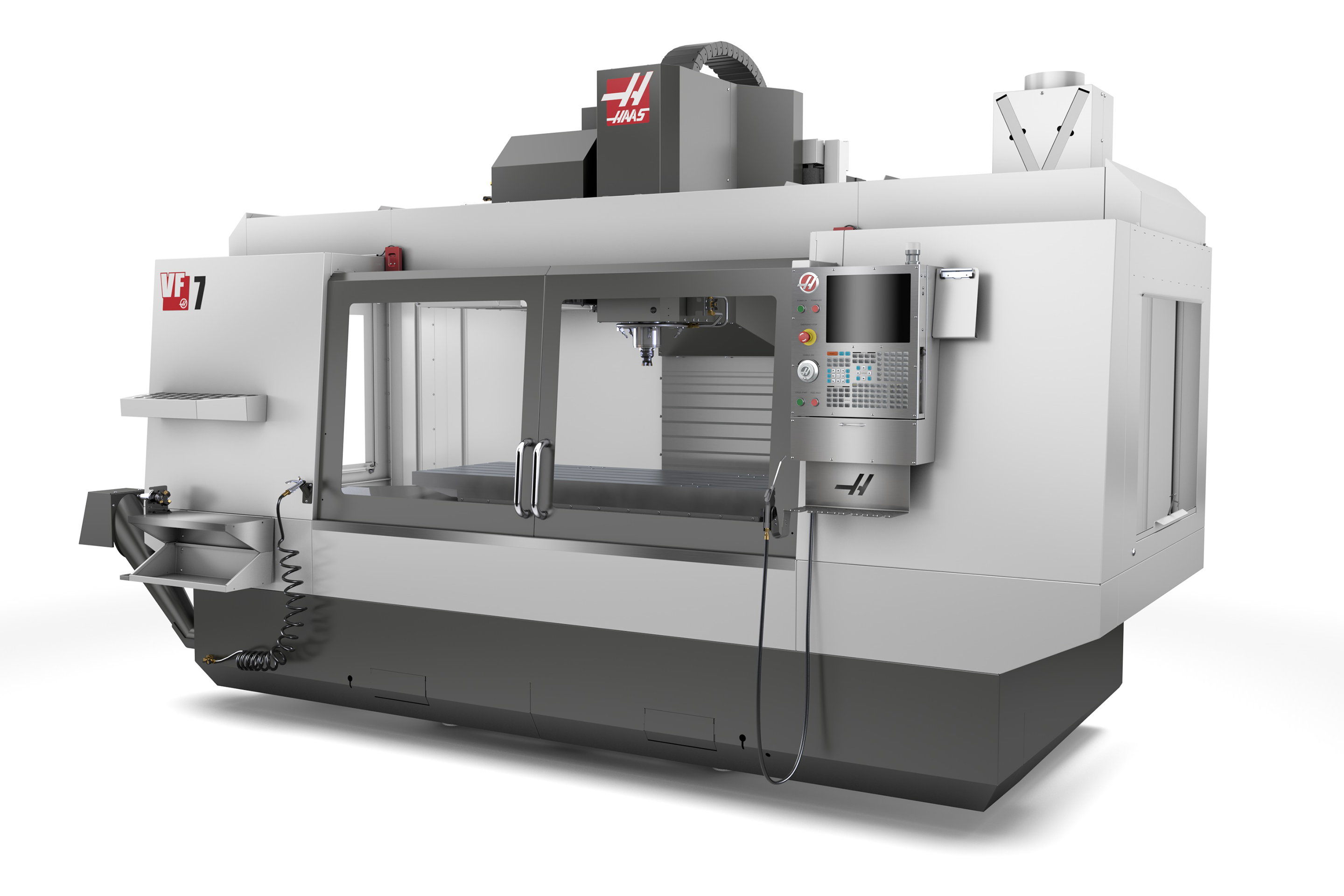

VMC:-

VMC machining refers to machining operations that utilize vertical machining centers (VMCs), which, as the name suggests, have vertically oriented machine tools. These machines are primarily utilized to turn raw blocks of metal, such as aluminum or steel, into machined components. They can be used to perform a variety of machining operations, including, but not limited to, the following: cutting, drilling, tapping, countersinking, chamfering, carving, and engraving. This versatility, combined with their relatively low cost, has made them a highly common machine shop tool. VMCs can be utilized for not only cutting, but also drilling, carving, engraving, tapping, countersinking, chamfering and many other applications.